The gleaming attract of important metals like gold, silver, and platinum has captivated humanity for millennia. nevertheless, the normal path from subterranean ore to polished product or service carries a significant environmental and social burden. Mining is resource-intense, usually disruptive to ecosystems, and generates substantial squander and carbon emissions. As world wide recognition of sustainability deepens and useful resource scarcity turns into a tangible issue, industries greatly reliant on these metals – particularly jewellery, electronics, and investment decision sectors – facial area mounting pressure to undertake more accountable procedures. The solution lies not merely in reducing consumption, but in essentially rethinking the lifecycle of those beneficial resources. Enter the circular financial state: a product focused on doing away with waste and continually reusing resources. within just this paradigm, recycled or regenerated metals are paramount, as well as technological know-how enabling their efficient, significant-top quality reprocessing could be the critical linchpin. Highly developed constant casting technological know-how, such as vacuum continuous casting equipment available wholesale, stands for the forefront of this transformation, supplying a robust Alternative to turn yesterday's scrap into tomorrow's treasures, sustainably and effectively.

Table of contents:

Mastering the Melt: excellent Casting effectiveness for Recycled Metals

sprucing the eco-friendly regular: Driving metallic Recycling in the Jewelry field

Forging the Future: setting up Closed-Loop important metallic Supply Chains

Lean and clean up: Reducing source squander and Environmental stress

Global Alignment: Meeting plan calls for and Market anticipations

Mastering the Melt: outstanding Casting efficiency for Recycled Metals

Recycled precious metals, sourced from article-client goods (like aged jewelry or electronics) or industrial scrap, inherently current distinctive worries when compared with virgin ore. They frequently consist of trace impurities, different alloy compositions, and require very careful managing to revive their desired Attributes. regular casting techniques, specially batch procedures, can wrestle with these inconsistencies. reaching uniform composition and protecting against defects gets to be more difficult, perhaps compromising the final merchandise's good quality and benefit.

This is where modern-day continual casting equipment demonstrate a distinct advantage. created for precision and consistency, these units excel in processing recycled feedstocks. crucial general performance Rewards include:

Homogenization Capabilities: Advanced steady casters frequently include complex mixing and melting mechanisms. These make sure a variety of recycled inputs, even with slight compositional discrepancies, are thoroughly blended within the molten bathtub. This ends in a really homogenous remaining item – whether or not It really is wire, rod, strip, or granules – minimizing variations and guaranteeing reliable metallurgical Houses batch immediately after batch. This is certainly crucial for applications like jewelry wherever colour, workability, and fineness standards are exacting.

specific Temperature Handle: keeping the exceptional melting and casting temperature is vital, especially with recycled alloys That may have reduce or varied melting details as a consequence of pre-current factors. ongoing casting techniques employ highly correct temperature sensors (like thermocouples) and complicated Command loops (generally PLC-primarily based). This prevents overheating (which may result in metal loss through vaporization or unwelcome reactions) and underheating (that may induce solidification difficulties and defects). This precision conserves Power and, critically, safeguards the integrity and top quality on the recycled steel through its transformation.

Impurity administration: even though pre-processing is crucial, some slight impurities could possibly continue being in recycled feedstock. steady casting systems, significantly People working underneath vacuum or controlled atmospheres, can mitigate the adverse outcomes of particular impurities. For example, a vacuum ecosystem helps prevent oxidation in the course of melting and casting, a typical problem that may degrade metal high quality and result in losses. managed stirring and stream in the crucible and die could also enable manage the distribution of any unavoidable inclusions, lowering their effect on the final item's structural integrity.

By successfully addressing the inherent difficulties of recycled components, steady casting technologies makes sure that secondary valuable metals is often reborn with good quality nearly indistinguishable from their Major counterparts.

Polishing the Green Standard: Driving metallic Recycling in the jewellery business

The jewellery sector, An important shopper of gold along with other valuable metals, is significantly beneath The customer and regulatory spotlight click here with regards to sustainability. The narrative is shifting from purely aesthetic worth to encompassing ethical sourcing and environmental duty. Continuous casting technology is a powerful enabler for jewelry manufacturers searching for to embrace this change:

Maximizing Secondary Resource Utilization: By efficiently and reliably processing recycled gold, silver, and platinum team metals (PGMs), ongoing casters enable jewelers to noticeably maximize the percentage of recycled written content of their items. This instantly lowers their dependence on newly mined materials, conserving normal methods and lessening the connected environmental footprint. Manufacturers can confidently convert scrap jewelry, workshop filings, and in many cases refined electronic waste again into large-excellent casting grain, wire, or sheet suitable for new creations.

minimizing the Carbon Footprint: Mining and refining Main metals are Power-intensive procedures with considerable greenhouse gasoline emissions. Recycling metals demands noticeably a lot less Electrical power – often cited as up to ninety-ninety five% much less for metals like gold and aluminum when compared with Major output. By integrating constant casting of recycled metals into their workflow, jewelry firms can demonstrably reduce their operational carbon footprint, a crucial metric for sustainability reporting and manufacturer positioning.

Aligning with "inexperienced Jewelry" and Certification developments: buyers are progressively seeking out brands that align with their values. conditions like "eco-pleasant gold," "sustainable silver," and "recycled information" are becoming strong advertising differentiators. Moreover, marketplace criteria and certifications, for instance All those promoted through the accountable Jewellery Council (RJC), normally emphasize or mandate the usage of recycled components and supply chain traceability. continual casting presents the specialized ability to meet these needs, supporting organizations obtain certifications, enhance transparency, and Develop consumer rely on. This strengthens brand track record and opens doors to environmentally mindful markets.

Forging the Future: constructing Closed-Loop Precious steel source Chains

the final word target of a round economic system is to produce shut-loop devices wherever resources constantly cycle back into use, minimizing squander and the necessity for virgin inputs. Continuous casting technological know-how is instrumental in acknowledging this vision for valuable metals:

Enabling entire-Circle producing: picture a process the place a company procures Licensed recycled gold, uses a continual caster to supply wire and sheet for jewellery creation, collects all internal scrap (sprues, filings, off-cuts), re-melts and re-casts this scrap utilizing the exact efficient machine, and perhaps even partners with retailers or focused recycling companies to reclaim post-purchaser items. steady casting would make the "re-Solid" step seamless and productive, closing the loop throughout the production facility alone or in a tightly integrated source chain.

Synergy with Recycling Infrastructure: The success of continual casting for recycled metals encourages more powerful collaboration between makers and also the metal recycling ecosystem. Refiners who obtain and procedure scrap can supply companies with significant-excellent recycled feedstock, being aware of it could be proficiently converted. Conversely, manufacturers making use of constant casting can offer cleaner, additional easily processable scrap back again to the recycling stream. This symbiotic romantic relationship strengthens the whole round price chain.

successful inside Scrap Reprocessing: Among the most immediate Rewards for brands is the opportunity to manage their particular procedure scrap successfully. in lieu of selling worthwhile scrap at a discount or coping with complicated external refining logistics for compact quantities, in-dwelling continuous casting permits the immediate reintroduction of sprues, runners, casting trees, and bench filings back again into the output cycle. This maximizes material utilization, decreases losses, and lowers General output prices. The ability to carry out modest, Recurrent melts tends to make this internal recycling extremely practical.

Lean and cleanse: decreasing Resource Waste and Environmental stress

Beyond enabling recycling, the inherent design of continuous casting features considerable pros in useful resource effectiveness and environmental impact as compared to classic strategies:

Minimizing substance Loss: common batch casting, involving crucible pouring and mildew filling, generally leads to substance left behind during the crucible (cranium), spillage, and better oxidation losses because of prolonged exposure of molten metal to air. constant casting, by contrast, draws metallic straight from the soften pool via a die in the managed fashion. this method minimizes residual steel, minimizes oxidation (especially in vacuum or inert gasoline designs), and results in better Total substance yields. considerably less metallic squandered indicates significantly less Main resource extraction is necessary after some time.

Optimized Batch Flexibility: Continuous casting devices are sometimes adaptable to varying output desires. They can operate repeatedly for big volumes but are also remarkably economical for scaled-down, specific batches. This flexibility makes it possible for brands to supply just what they will need, when they will need it, steering clear of the need to soften excessive quantities of steel simply to fill a large crucible for a small get. This "ideal-sizing" of manufacturing runs helps prevent pointless Strength intake and possible squander connected to overproduction or storing excess molten metallic.

lessened Environmental Load: The efficiency of ongoing casting translates to reduced Power consumption for each device of steel cast when compared to significantly less managed batch methods. specific temperature Command helps prevent Strength waste from overheating. In addition, units created with contained melting zones and opportunity integration with fume extraction or managed atmospheres (like vacuum or inert gas) appreciably decrease the release of fumes and thermal radiation into your working natural environment and the broader ambiance. This contributes to a safer place of work along with a reduce General environmental affect.

world-wide Alignment: Meeting plan calls for and industry anticipations

The force in direction of circularity is not only an environmental suitable; It can be ever more getting a regulatory necessity as well as a market place expectation, specially in formulated economies:

Compliance with Worldwide requirements: marketplaces in Europe and North The usa are progressively implementing restrictions and specifications favouring or mandating the use of recycled supplies. Certifications such as dependable Jewellery Council (RJC) Code of tactics consist of stringent specifications for product provenance and chain of custody, strongly encouraging using recycled sources. Utilizing Sophisticated casting engineering created for recycled metals assists organizations fulfill these compliance obligations, making sure market access and averting potential trade obstacles. Sourcing machinery from the reliable gold continuous casting device supplier who understands these compliance demands is important.

Driving ESG method and Trader self confidence: Environmental, Social, and Governance (ESG) criteria are actually central to company technique and Trader relations. Demonstrating a dedication on the circular financial system by tangible actions, like buying technology for recycled steel processing, appreciably boosts an organization's ESG profile. This draws in sustainability-concentrated traders, boosts company track record, and may even bring about preferential funding conditions.

Building eco-friendly provide Chain Competitiveness: As important manufacturers and retailers decide to ambitious sustainability targets, These are cascading these necessities down their provide chains. Suppliers who can verifiably offer you merchandise made with superior recycled content material, processed employing efficient and cleanse systems like ongoing casting, gain a significant aggressive edge. They turn out to be favored associates, superior positioned to earn environmentally acutely aware procurement contracts and Make long-phrase, resilient enterprise relationships. For organizations trying to scale these efforts, exploring vacuum ongoing casting device wholesale options can offer the required capacity effectively.

The changeover to a circular economic system for precious metals is now not a distant prospect but an urgent necessity and a tangible chance. Recycled metals give a pathway to significantly decrease the environmental affect related to our desire for gold, silver, and platinum. even so, noticing the total likely of such secondary methods hinges on adopting the ideal processing technologies.contemporary continuous casting equipment stick out to be a significant enabler Within this transition. Their capability to cope with the nuances of recycled feedstock, sustain Fantastic top quality standards, combine seamlessly into closed-loop devices, limit squander, and align with international sustainability goals can make them indispensable equipment for forward-imagining organizations. By embracing this technology, organizations from the jewellery, refining, and electronics sectors can not simply increase their operational effectiveness and products high quality and also improve their manufacturer status, meet up with evolving marketplace calls for, and contribute meaningfully to a far more sustainable and resource-acutely aware potential.For businesses seeking to put into action these Innovative capabilities, solutions just like the Gold Continuous Casting Machine (TAKJ-CC) from Taeantech exemplify the type of technologies driving this transformation, presenting capabilities especially made to help the efficient, higher-high quality casting of the two virgin and regenerated treasured metals in a framework of environmental duty.

Jennifer Grey Then & Now!

Jennifer Grey Then & Now! Ralph Macchio Then & Now!

Ralph Macchio Then & Now! Romeo Miller Then & Now!

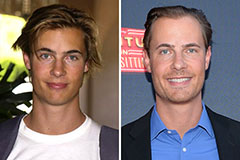

Romeo Miller Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!